When it comes to preventing product loss due to broken tools continuing to run in a CNC machine, Ultra Tool's FEM Broken Tool Sensing Device has you coverd.It will detect a broken tap, drills, reamers or product and automatically shut down production in your CNC Machining Center. This will save you thousands of dollars by protecting the product from getting damaged. This state of the art device is simple to install, and is already in use at top auto manufacturers around the world, replacing inferior and outdated phototube and acoustic emission sensors.

The FEM Broken Tool Sensing Head is controlled by a microcomputer and features a fully sealed air tight (ISO IP67 Waterproof), so there are no side effects from machine vibration, coolant, oil, or chips from the CNC machine. It detects a broken tool when the sensing needle's full rotation is compromised, the Sensing Device sends a signal that shuts down the CNC Machining Center. It operates under a high-precision DC Swiss motor that drives the needle and the control unit’s IC circuits and the microcomputer guarantees its quality and reliability.

The Broken Tool Sensing Device can be used in a wide variety of NC machines, such as Lathes, Drilling Machines, and NC Machining Centers, as well as in Transfer, Rotary Index, Tapping, Multiple Drilling, and Automatic Assembly Machines.

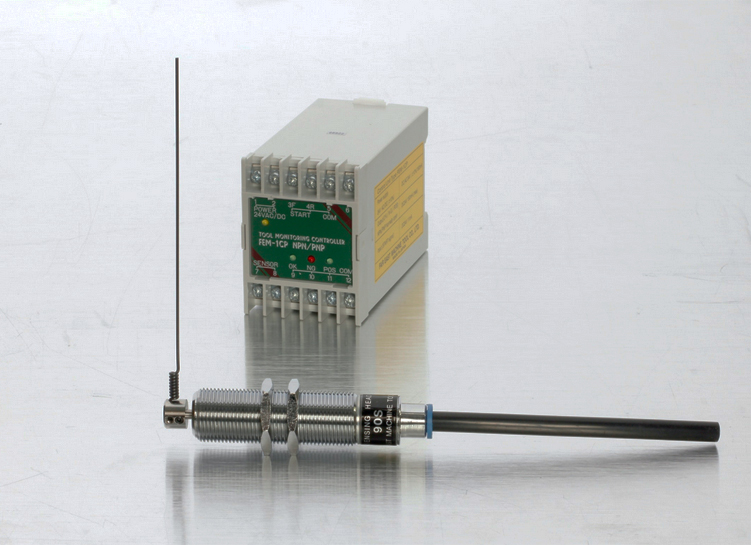

The FEM Broken Tool Sensing Device includes a control unit and sensing head.

Rotating Angles of the Sensing Head

Sensing Heads are available through Ultra Tools in 45, 60, 90, 120, and 180 degrees. The rotation of the sensing needle can be directed to either a clockwise or counterclockwise rotation.

Adjustment and Replacement of the Sensing Needle

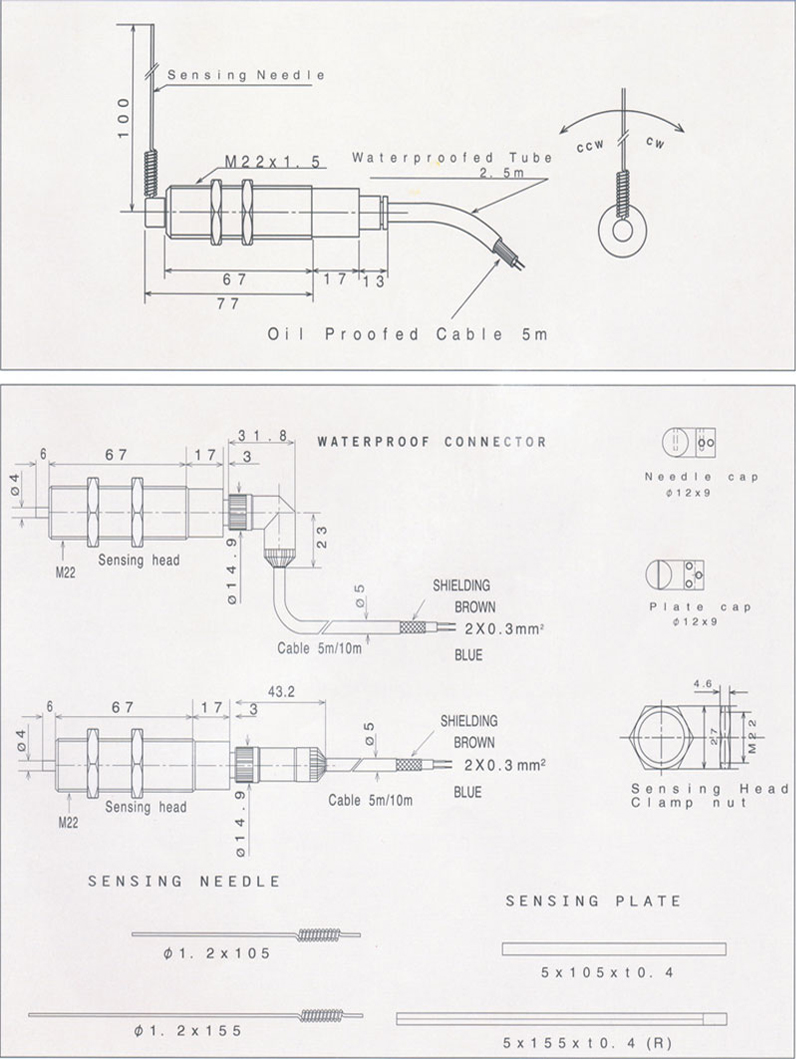

The standard length of the sensing needle ranges 100mm to 150mm. The sensing needle is attached to the head cap by two set screws. The head cap and motor axis can easily be set to any position by a simple set screw adjustment.

Sensing Area

The sensing area is 15-20 degrees from where the sensing head begins its sweeping motion to with in 10-25 degrees of the stop end of the motion. In order for the self-monitoring function to operate properly, adjust the head cap so that the tool to be detected is a close as possible to the center of the full angle of the sensing area.

Self-Monitoring Functions

The Fem Broken Tool Sensing Device has a built-in self-monitor. This feature checks for breaks or shorts in the cable wire, changes in the sensing head voltage, and rotation speeds of the sensing head.In case of a short circuit or a disconnection of wires, the red led on the Control Unit will blink and the machine will stop immediately.

Rest Functions

The two reset functions of the FEM Broken Tool Sensing Device determines the length of the output signals. The output signal can either be continuous or brief depending on your needs

Sensing Head and Control Unit Specification

SHOP NOWBROKEN TOOL DETECTOR FOR CNC MACHINES

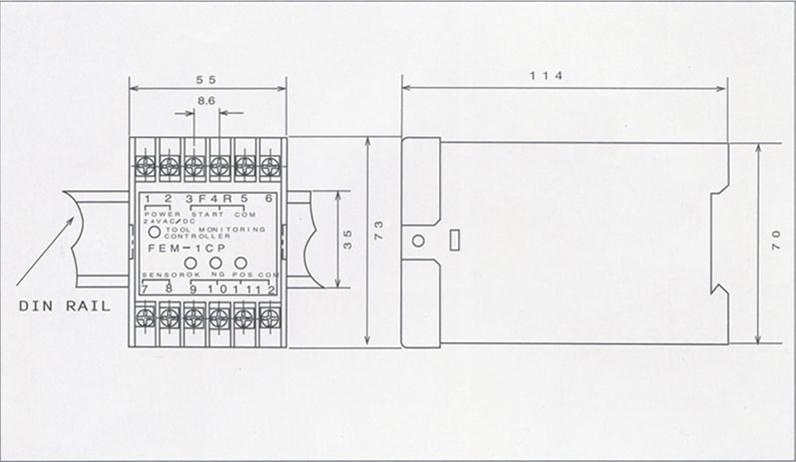

FEM-1CP CONTROL UNIT (for one sensing head)

CONTROL UNITS CONNECTING TERMINALS

SPECIFICATIONS OF FEM BROKEN TOOLS SENSING DEVICE CONTROL UNIT (FEM-ICP) AND SENSING HEAD (FEM-1S)

| CONTROL BOX | UL approved. DIN rail grooves. |

|---|---|

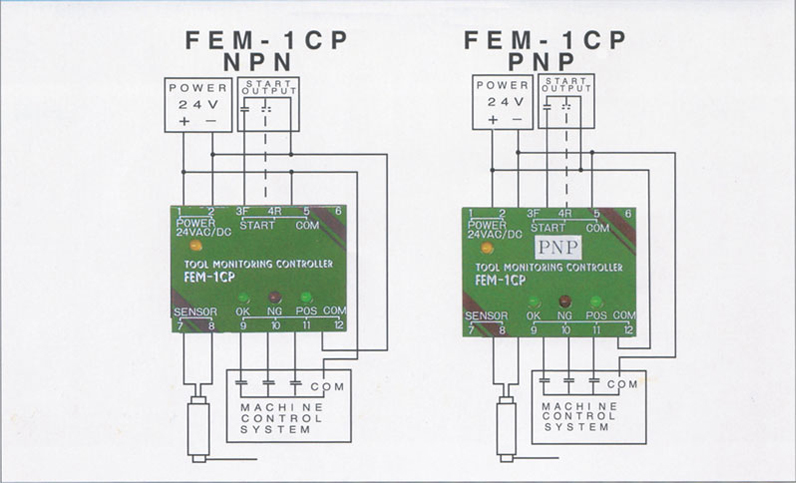

| POWER | 24V AC/DC (10%) 150mA |

| INPUT(Start) | Contact Capacity DC 24V 11mA |

| OUTPUT SIGNALS(OK, NG, POS) | NPN .PNP Transistor-Open Collector DC 24V 150mA |

| SELF MONITOR | A circuit to detect any irregularities in the sensing head. |

| INDICATORS | Luminous LED,Yellow: Power,Green: OK (Good),Red: NG (No Good),Green: POS. (Position),Flashing Red: Self-Monitor |

| DIRECTION OF ROTATION (CW or CCW) | Can be selected on DIP switch |

| TERMINALS | 12 terminals |

| TEMPERATURE (Work Area) | 0° C ~+50° C(do not freeze) |

| HUMIDITY (Work Area) | 35~ 85% RH(do not frost) |

| RESET FUNCTION | "A" reset and "B" reset |

DETECTION TIME

| 45S=0.44"60S=0.45"90S=0.51"120S=0.6"180S=0.62 |

|---|

SENSING HEAD

| HOUSING | chrome plated |

|---|---|

| MOTOR | DC motor, high precision, Swiss made |

| WATERPROOFING | ISO specification of IP 67 |

| DEGREES | Available in 45° 60° 90° 120° and 180° |

| CABLE | OIL PROOFED. 5m length as standard |

| TEMPERATURE | 0° C ~ +50° C(do not freeze). |

SENSING NEEDLE

| MINIMUM LENGTH | 100mm ( Standard round or plate) | Plate 100mm |

|---|---|---|

| MAXIMUM LENGTH 150mm | 150mm ( round or plate) | Plate 150mm |